In manufacturing and equipment-run industries, one issue is always going to be reoccurring, machine downtime. It’s unavoidable and the longer machines are down, the more money is lost. A lack of time and expert technicians only makes the problem worse.

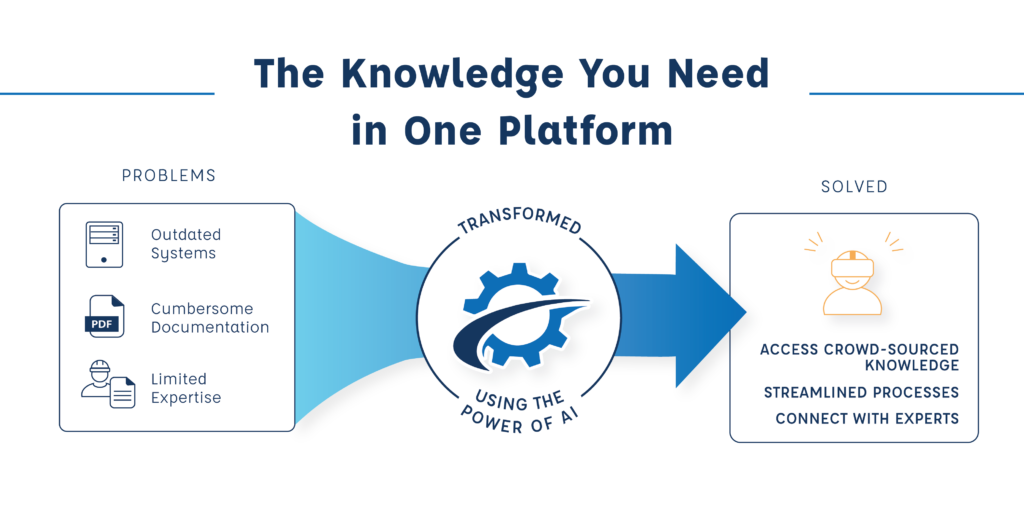

NewForge has been focused on helping companies address this problem for years now. Their new platform, Knowledge Place, is now using Artificial Intelligence (AI) to bring companies the vital knowledge they need to get machines running as soon as possible.

What is Artificial Intelligence (AI)?

If you haven’t heard about AI, the concept can be simplified into mechanical “systems that act like humans,” according to IBM.

Artificial Intelligence has been around for a fairly long time. Conceptually, there have always been stories about artificial beings or machines that recreate human intelligence. Think of HAL 9000 in Stanley Kubrik’s 2001: A Space Odyssey or even farther back, Mary Shelley’s Frankenstein.

However, the term was first introduced in 1956 by John McCarthy during the Dartmouth Workshop where the goal was to make machines capable of human intelligence. John McCarthy has since been coined the “Father of Artificial Intelligence”.

But it wasn’t until around January 2023 that AI surged in popularity, with OpenAI’s introduction of ChatGPT-3. ChatGPT is a language processing tool that chats with a user. Unlike other chatbots, ChatGPT can remember and refer to things previously discussed in the conversation, simulating human-like interactions.

Overnight, ChatGPT became a household name. People found that it could be used to not only answer questions but also assist with tasks like writing emails, code, and essays.

NewForge Prior to AI

Before the introduction of AI into their solution, NewForge’s focus was creating custom augmented reality (AR) solutions for manufacturing and logistics that increase efficiency for their clients.

Here’s a simplified example of how their previous solutions worked: On the plant floor, a technician would wear a pair of smart glasses (picture a tablet that sits next to your eye) and receive all the instructions on how to do their task right on the screen. All they have to do is say out loud, “Continue” and the glasses will take them to the next step in their process.

If something went wrong, the technician could also call for help using their smart glasses. Through the camera, someone could see what they’re doing almost like they’re standing over their shoulder.

This solution helps frontline workers get their work done faster and reduce downtime all while reducing error rates.

Even though NewForge’s AR solutions have a surplus of benefits, NewForge noticed that some companies struggled with creating the instructions that go on the smart glasses.

ExpertAI: Say Hello to Instant Work Instructions

“It’s a massive pain in the ass,” Javier Ortiz, CEO and Co-founder of NewForge, said. “Nobody wants to recreate work instructions.”

“If you ask somebody that’s on the manufacturing floor… if you could have anything when it comes to work instructions, what would you want?”

People would tell you they want them to instantly POOF be created, Ortiz explained. “So that’s basically what we’re adding,” Ortiz said, referring to their new AI feature, ExpertAI.

ExpertAI is a new feature for NewForge’s comprehensive knowledge-sharing platform, NewForge Knowledge Place.

The generative AI tool not only provides quick troubleshooting answers but also creates work instructions for manufacturers. It eliminates the need for someone to take hours out of their day to recreate their processes into AR work instructions.

ExpertAI is one-way users can get instant help on Knowledge Place, but not the only way. Knowledge Place also provides a repository of machinery experts that users can schedule an appointment with and get instant help right when they need it.

How does ExpertAI work?

In simple terms, ExpertAI works similarly to ChatGPT. Except all its knowledge is surrounding equipment maintenance. A user simply writes in a question or request and the system responds.

For example, you could ask ExpertAI to help you troubleshoot your CNC machine or prompt it to create inspection instructions you could follow on your phone or smart glasses.

People usually have two main questions about ExpertAI: Where does the information come from? How do you keep things accurate?

To answer both, ExpertAI gathers information and learns from its users. Through NewForge’s “Feed the AI” feature, professionals can insert manuals, pictures, or any other form of media that the AI can then use to learn from.

One extremely useful feature is that ExpertAI can also learn from support calls. We have customers with all these previously recorded live calls that have the answers in them that are just going to waste, Ortiz said. Recorded calls are simply transcribed into written words that the AI can pull information from.

Users always have the option to give ExpertAI feedback on the responses it gives them.

For example, if a user were to prompt it for a set of instructions for calibrating a machine and step 4 wasn’t right, the user can let ExpertAI know to adjust that step.

From then on, the system knows that it needs to improve in that area and works to solve the issue or alert staff to let them adjust.

Is AI Taking my Job?

The short answer, No.

When looking at ExpertAI in the manufacturing, logistics, and equipment maintenance fields, it addresses gaps that desperately need to be filled. Not to take away work that’s going to be missed.

In these industries, there are just not enough people with the time or skills to create instructions, organize manuals, or do any of the other tasks that are essentially just to give other people the knowledge they need.

In addition, enterprises that use Knowledge Place (and ExpertAI in particular) for customer success, have more time to help more customers. Instead of spending an hour on a call for a simple question, customers can get instant feedback from the AI, also increasing their satisfaction rates.

When it comes to machine maintenance and repairs, sometimes, you just need to talk to another person. NewForge looks to use ExpertAI as its first line of defense against equipment downtime, not its only line of defense.

Knowledge Place also allows you to find experts in specific machinery and book an appointment to get help. These experts are then paid for their time and effort through the platform.

NewForge Knowledge Place is designed to be the knowledge tool that has all the help you need in one place.

What’s the Future of AI & ExpertAI?

The future of AI is dynamic with promises of changes in our society, economy, and technology. As it continues to find a place in our society, it’s important to find ways that it can be used to solve long-term issues and pain points.

NewForge has developed a way to implement AI in industries that are in desperate need of assistance.

As it currently stands, ExpertAI is in the development stage on Knowledge Place, but it should be ready for the public in early March according to Ortiz.

In the meantime, other features are ready to be used on the Beta of Knowledge Place. NewForge is currently seeking new users to join the forefront of the maintenance revolution.

To learn more about NewForge Knowledge Place or its ExpertAI feature check out the site or reach out to the NewForge team at [email protected]