The post The New Face of Equipment Repair: Remote Expert Help first appeared on NewForge Tech.

]]>By leveraging the latest technologies to connect with experienced technicians from around the globe, manufacturing companies are able to quickly and efficiently diagnose, troubleshoot, and repair their equipment with minimal disruption. Remote experts (‘experts’ are subject-matter specialists who have expertise on a specific piece(s) of equipment) offer an efficient solution for manufacturing companies looking to overcome labor shortages and quickly repair equipment remotely.

The labor shortage in the manufacturing industry

The manufacturing industry has long been a cornerstone of the global economy, creating countless jobs, and producing essential goods that we use on a daily basis. However, the industry is facing a major challenge: a shortage of skilled labor. This labor shortage has become especially severe in recent years, and it is estimated that the U.S. manufacturing sector will lose 3.5 million skilled workers to retirement in the next decade. If this continues, by 2030, there could be 2.1 manufacturing jobs available with no one to fill them leading to a potential cost of 1 trillion dollars.

The labor shortage in the manufacturing industry is a result of several factors, including the aging workforce and the lack of skilled workers. In addition, the negative perception associated with working in the manufacturing industry has made it difficult for manufacturers to attract and retain talent. As a result, the industry is struggling to find workers to fill the increasing number of job vacancies.

The challenges faced by manufacturers due to the labor shortage

The labor shortage is not just a problem for manufacturers; it has also created a ripple effect throughout the economy. Manufacturers are facing a significant challenge in meeting production demands, which is leading to delayed shipments, loss of revenue, and customer dissatisfaction. Moreover, the shortage of skilled workers is impeding the innovation and advancement of the industry, which may have long-term impacts on its growth and sustainability.

According to a survey through the National Association of Manufacturers, the #1 business challenge facing 75% of manufacturing leaders in the U.S. is attracting and retaining quality workers. At the beginning of the pandemic, the U.S. lost 1.4 million manufacturing jobs, and while two-thirds of those came back, it still left a hole in the manufacturing workforce.

Manufacturers should consider using remote experts for equipment repair

Manufacturing has been greatly affected by the labor shortage, which can cause equipment downtime and production delays. However, with technology advancements, manufacturers now have access to remote experts, who can help address these issues.

Who are remote experts?

Remote experts are subject-matter experts who specialize in the maintenance and repair of machinery. They connect virtually with an employee of a business and provide valuable support services such as troubleshooting, repair consultations, assistance with diagnostics, parts replacement, and programming. Remote experts not only offer a cost-effective solution to equipment maintenance but also help reduce downtime due to their quick response times.

What is remote expert technology & how is it better than a phone or video call?

Remote expert technology is specialized software that enables a manufacturer’s staff or equipment technician to connect with an off-site expert to repair equipment.

One vehicle for this technology is smartglasses. The technician wears the smartglasses and the expert, who is working from a remote location, is logged into the software’s dashboard and can see everything the technician sees via the camera. The technician can work hands free and move around the equipment and the facility, while the expert guides them through the repairs. It’s as if the expert was standing right there with the technician. This approach decreases the need to travel in-person, fixing the problem in days, not weeks.

Many smartglasses companies and software providers have seen the practical use for the smartglasses in the industry and have adapted their hardware and software for the environment. With improved safety measures and sturdy yet light designs, technicians don’t have to worry about smartglasses inhibiting their safety or getting damaged while in use. And while most remote calling softwares work on smartglasses like Microsoft Teams and Zoom, they weren’t created with industry in mind. Many remote expert softwares enable the expert to share annotations of what they see to the technician on the other end, highlighting, for example, a missing bolt a technician may be overlooking. In addition, experts have the ability to share schematics, manuals, and PDFs all in someone’s line of sight as they work. This combination of highly customized software and hardware for the industry creates a direct and easy way of communicating that effectively saves time, money, and resources.

Assisted reality and remote experts can help manufacturers address the labor shortage

Remote experts can help manufacturers address the labor shortage by providing efficient and accurate repair services. This technology eliminates the need for on-site field service technicians, which allows manufacturers to access a larger pool of expertise at a lower cost than hiring full-time staff. Remote experts are also available 24/7, making them more reliable than traditional technicians who may be limited to business hours.

How equipment repair issues can be resolved remotely

Equipment repair issues can range from simple issues, such as replacing a part, to more complex problems, such as diagnosing a mechanical malfunction. Remote experts can help address these issues by providing real-time visual support and step-by-step instructions, which allows manufacturers to reduce the costs of travel for specialists to address the problem on-site with real-time support. For instance, a manufacturer in the packaging industry might encounter a problem with their shrink wrapping equipment in one of their facilities, and a remote expert in another state, or even another country, could help diagnose and fix the issue by virtually looking over the technician’s shoulder.

Other ways manufacturers can benefit from using remote help include using remote experts to improve their quality control measures. Additionally, remote experts can help their peers on the manufacturing floor with troubleshooting technical issues and identifying areas of improvement within the manufacturing process.

Case study

Bühler, a global supply chain company, utilized our Assisted Reality platform and saw a 35% improvement in efficiency, saving them $30k a day. They also experienced a 55% reduction in travel expenses and a 22% uptick in customer support satisfaction.

Cutting down costs with remote experts

Manufacturing companies often depend on efficient and effective machinery to keep production running smoothly. But when equipment malfunctions, these companies are left with a difficult choice: spend time and money bringing in an expert technician for repairs, or attempt DIY repairs that may not be successful. Fortunately, there is now a third option, using remote experts for equipment repair.

How remote experts can help manufacturers avoid costly downtime

First and foremost, remote experts can help manufacturers avoid costly production downtime. When equipment fails, it can result in a significant loss of production, which ultimately leads to a decline in revenue. A remote expert can identify the problem quickly and provide real-time guidance to get the equipment running again, minimizing downtime and the associated costs.

Additionally, remote experts offer up their expertise to younger and less experienced technicians, enabling them to learn from more experienced professionals.

More cost benefits of using remote experts

Remote experts allow you to save costs on travel expenses. In traditional repair methods, when a machine breaks down, manufacturers either have to wait for a technician to arrive at their plant or, depending on the equipment, send the machine to a repair facility. With remote expert solutions, manufacturing companies can contact experts virtually via the NewForge Knowledge Place platform while using assisted reality to receive real-time guidance to repair the issue without anyone needing to travel. Therefore, manufacturers can save costs in travel expenses such as transportation and accommodation. It’s a win-win situation where both the manufacturer and expert save time and expenses.

Furthermore, remote experts provide better cost predictability. Traditional repair methods are costly due to unpredictable expenses, such as delays in travel, out-of-hours work fees, and unexpected maintenance expenses. With remote expert solutions, manufacturers can expect fixed costs with no hidden fees other than subscription or service fees. As a result, the manufacturer can plan their budget efficiently and allocate funds to other essential areas of their business.

Remote expert services versus traditional repair methods

In terms of cost comparison, remote expert solutions are more cost effective than traditional repair methods. Manufacturers only have to pay for remote expert technicians when they need them, making it more affordable in the long run.

The future of remote expert technology in manufacturing

The potential of remote expert technology to revolutionize the manufacturing industry is truly an exciting prospect. Augmented reality (AR) technology is predicted to become more commonplace among manufacturing companies. It allows experts to “see” and diagnose problems with machines in a virtual environment, providing them with additional insight into the issue.

From increased efficiency and productivity to cost savings and improved customer experiences, remote expert technology in manufacturing is certainly something to keep an eye on. Stay tuned for additional Knowledge Place features that will greatly enhance the future of work!

The post The New Face of Equipment Repair: Remote Expert Help first appeared on NewForge Tech.

]]>The post AR: How Its Expediting Growth in the Manufacturing & Logistics Space first appeared on NewForge Tech.

]]>Overview of AR’s prevalence in the manufacturing and logistics space

Augmented Reality technology is helping the manufacturing and logistics industries. It is used in warehousing, inventory management, assembly & maintenance, quality control & inspection, as well as employee training & onboarding. AR technology can provide real-time guidance and visual aids to workers, helps reduce errors or accidents, enables more informed decisions, and facilitates better quality control. It also helps reduce training time and costs, improves the learning experience of new hires, and provides insights into workers’ performance. AR can help to improve operational efficiency, accuracy, safety, and customer satisfaction.

Unlocking the benefits of AR in the manufacturing and logistics space

Innovation is a vital aspect of every industry, including logistics and manufacturing. The use of augmented reality (AR) is gaining traction in the manufacturing and logistics industries. With its ability to provide real-time data, AR can increase efficiency, reduce costs, and improve safety in these sectors. By understanding and embracing the potential of AR technology, companies in manufacturing and logistics can unlock a new level of productivity, accuracy, and safety for their operations. Here are four benefits it can offer.

Increased efficiency

One of the most significant impacts of AR is its capability of enhancing operational efficiency. By using AR in manufacturing or logistics, companies can streamline their operations, identify errors quickly, and take proactive measures to address them. For example, the use of AR enables employees to access real-time information on specified tasks alongside their instructions. This, in turn, helps them complete tasks quickly, improve decision-making, and reduce any delay. For example, the use of AR in logistics can take an employee through their entire picking process, giving them real-time feedback as they go through their processes.

Reduction of human error

One of the common problems that manufacturing and logistics companies face is human error. For instance, an employee could load the wrong package onto a delivery truck, resulting in delays and lost productivity. AR can help reduce these incidents by providing instant real-time information and instruction to employees. For instance, wearable AR devices such as an AR headset can display step-by-step work instructions taking an employee through all the steps in a manufacturing or logistics process. Additionally, AR helps reduce the time employees spend manually updating and managing documents, freeing up their time to do more meaningful tasks that positively impact the business.

Increased safety

Safety is a major concern in manufacturing and logistics. AR can enable workers to access real-time information on potential hazards in the workplace. For instance, a worker wearing an AR headset can receive proactive warnings alerting them about hazardous equipment, machines, or dangerous exposure areas. AR can also help remotely guide employees through complex procedures, reducing the need for human intervention and reducing the risk of injury.

Improved visualization

AR along with virtual reality allows employees to see virtual products in real-time and can help employees visualize the assembly process before production begins. Engineers or designers can visualize the final product and identify any design flaws or issues early. This also enables engineering teams to collaborate remotely in real-time, increasing collaboration and reducing the time to market.

How augmented reality is revolutionizing manufacturing and logistics space

One of the most impactful technological advancements that have been changing the way manufacturing and logistics industries function is Augmented Reality (AR). AR is an interactive experience that enhances the real world by overlaying digital information onto it. Here is a look at a few ways augmented reality is used with manufacturing and logistics.

Warehouse operations

Employees in warehouses can wear AR smartglasses as a way to streamline their processes and operations. By wearing smartglasses, employees get step-by-step instructions in their line of sight guiding them through their process while doing it. In warehouses, these are typically combined with scanners and QR codes to avoid any errors. For example, a pair of smartglasses will let a worker know to go to aisle 1A and ask the user to scan the QR code of that aisle to confirm they’re at the right place. Similar functions like countbacks help warehouse employees reduce their pick-up time and increase the accuracy of the picking process. AR technology allows for warehouses to streamline their process and increase overall productivity.

Product Design

AR is also changing product design in the manufacturing industry. With the use of AR, designers can visualize new products in the real world in real-time, reducing the time needed for physical prototyping. AR also gives designers the ability to test and refine products by receiving real-time feedback on the performance of the product during the design process. Designers can also review assembly processes, identify bottlenecks in the production line, and visualize end-user actions, enabling them to optimize product design for mass production.

Inventory Management

Managing inventory is a significant challenge in the manufacturing and logistics space. However, with AR, inventory management has become more streamlined and accurate. By using AR-powered systems, such as smart shelves, warehouse management along with warehouse employees can keep track of products in real-time without any human intervention. AR-powered smart shelves use sensors and cameras to monitor products as they move on and off the shelves. This helps keep track of inventory in real-time and also helps employees maintain stock levels. In addition, AR systems can send the details of goods that are running low or in stock directly to the logistics department, which allows for quicker and more accurate restocking.

How NewForge helps address AR technology challenges in the manufacturing and logistics space

As AR technologies keep on evolving, businesses and industries need to keep up with these advancements to remain competitive. Augmented Reality (AR) technology revolutionizes the manufacturing and logistics space, by improving efficiency and accuracy. However, the adoption of AR technology hasn’t been a smooth ride for most businesses. NewForge has helped businesses address many of the obstacles.

Securing sensitive data

AR technology is usually connected to the internet, which opens up the business to a myriad of cyber threats. Businesses in the manufacturing and logistics space deal with sensitive data, such as customer data, business strategies, and manufacturing processes. Therefore, there is a risk of hackers gaining access to this data when using AR technology. Thus, businesses need to put in place robust cybersecurity measures to protect their data from cyber threats. AR specialists, NewForge, takes security seriously and employs various measures to ensure the platform is secure for its users. These measures include data encryption, access controls, and regular security audits. Additionally, NewForge complies with industry standards for security and privacy, such as ISO 27001 and GDPR.

Difficulty integrating AR with existing systems

Integrating AR technology with existing systems can be a considerable task for businesses. Existing systems were designed and developed using the traditional system, making the integration of AR technology challenging. However, NewForge prides itself on being a system integrator for its enterprise clients, eliminating the headache that typically comes with integrating new systems. From consulting and planning to hands-on training and deployment, NewForge takes care of everything.

Lack of skilled personnel

There is a shortage of skilled personnel equipped with the technical know-how to handle and maintain AR technology. The manufacturing and logistics industries are relatively complex, and the technology changes daily, which calls for a highly skilled workforce. As a result, businesses need to invest in training their employees to handle AR technology or risk not getting the full benefits of the technology.

For enterprise clients, NewForge provides an end-to-end solution to proactively and successfully resolve skills-gap challenges. The process includes planning and consultation, change management, deployment and training, and customer success strategy.

Unfamiliarity and resistance to change

Lastly, businesses are reluctant to adopt new technologies or ways of doing things, mainly because of unfamiliarity and a perceived disruption of operations.

As with any new technology, it can take some time for employees to become comfortable using AR. Therefore, businesses should provide ongoing education and training to support employees as they get accustomed to working with the new technology.

Additionally, having the right devices and programs that support AR will help ensure a smooth transition.

Augmented Reality is a powerful tool for transforming the manufacturing and logistics industries. Its ability to quickly parse data from real-world environments and interact with users in an immersive way makes it well-suited for roles such as quality assurance, assembly, and job task analysis. Moreover, its great potential lies in its ability to create intuitive user interfaces which allow for faster data acquisition and improved decision-making. As the technology continues to develop, it is important that further research be conducted into the efficiency gains AR can bring to manufacturing and logistics operations.

The post AR: How Its Expediting Growth in the Manufacturing & Logistics Space first appeared on NewForge Tech.

]]>The post 5 Ways AR Enhances the Packaging Industry first appeared on NewForge Tech.

]]>How AR helps the packaging industry

In today’s fast-paced world, businesses need a competitive advantage and to continually evolve to keep up with the competition. The packaging industry, in particular, has seen significant changes over the years, with the advent of new technologies like Augmented Reality (AR). AR helps the packaging industry in many ways, making its operations more efficient and cost-effective.

The augmented reality product packaging process can be optimized to ensure that the packaging is done efficiently, reducing waste and speeding up production.

Increased efficiency in the manufacturing process

Efficiency is key to staying ahead in any industry. This is especially true in manufacturing, where every moment of productivity directly impacts the bottom line. Let’s talk about how efficiency in manufacturing can be further improved with AR.

Reduced downtime

The utilization of AR technology in the manufacturing industry leads to reduced downtime, which translates to increased productivity and profitability. With AR capabilities, employees can access real-time data on machines, processes, and products, providing immediate insights and repairs when necessary. The ability to troubleshoot problems quickly and efficiently through AR tech support means less time lost to downtime and more time dedicated to manufacturing. AR also allows for the creation and use of digital work instructions, helping employees stay on task and efficient, increasing their productivity.

Increased accuracy

Inaccuracies in manufacturing can cause product defects and recalls, resulting in reputational damage and financial loss. AR technology enhances the accuracy of the manufacturing process in the product packaging industry through visual overlays and step-by-step instructions on assembly, ensuring products are made to exact specifications. The use of AR technology in the manufacturing of complex products and equipment drastically decreases the likelihood of human error, leading to improved quality and safety standards.

Improved training and performance

The use of AR technology helps employees gain a deeper understanding of the manufacturing process and the equipment they operate. With the use of AR wearables like smartglasses, employees receive instructions while being hands-free to do the task at hand, allowing them to better understand and retain information. As a result, this leads to fewer errors, improved safety, and increased productivity.

Improved visualization of packaging solutions

With the help of modern technology, companies are now able to offer a more comprehensive product presentation and a personalized augmented reality experience to their customers. The potential of AR technology and even virtual reality to provide better visualization of packaging solutions can help customers and increase sales. Here are 3 ways in which AR technology can be used to enhance the customer experience.

Eliminating physical prototypes

Packaging design begins with prototypes, which can be time-consuming and require considerable resources to produce. With AR technology, designers can make changes to the package without the need for physical prototypes, which cuts down on development time and costs. Designers can create detailed 3D images of their AR packaging solutions that customers can rotate and zoom in on, and even test out in a real-world situation.

Convenience

Consumers are more likely to buy products that are easily available, and AR technology bridges the gap between physical stores and online shopping. Companies can integrate AR technology into their mobile applications, allowing customers to visualize products accurately, even when shopping from home.

Enhanced quality control

No matter the industry you’re in, quality control is essential to ensuring the success of your business. As technology continues to advance, the packaging industry is starting to leverage the power of augmented reality (AR) to take its quality control processes to the next level. Here are 3 ways AR can help you maintain high-quality standards for your packaging.

Reducing errors

One of the most significant benefits of AR is the ability to reduce errors in the quality control process. Many companies use AR technology to produce 3D visualizations of their product, allowing them to analyze it from every angle and identify any defects or issues before it reaches the customer. By catching potential errors early on, they can save their business from unnecessary expenses and maintain the quality of their products.

Companies can also reduce their error rates through assisted reality work instructions. By giving employees guided step-by-step instructions in their line of sight via smartglasses, the chance of human error is greatly reduced. These customized instructions can also integrate quality control steps like countbacks and submitting a photo that guarantee that no mistakes are being made.

Improved training

Another way AR enhances quality control is through improved training. AR technology provides a unique learn-by-doing approach, making it easier for employees to learn and retain new information like how to operate new equipment or assemble products correctly. This results in fewer errors and improved overall quality, helping you maintain a high level of customer satisfaction.

Cost reduction

Finally, AR also helps businesses save money in the long run. By reducing downtime, identifying errors early on, and providing efficient solutions, businesses can save on expenses related to repairs, maintenance, and even staffing. This results in a significant reduction in operating costs, boosting the overall profitability of your business.

Expedited troubleshooting

Traditional technical support can be time-consuming, expensive, and often frustrating for both support agents and customers. That’s where AR technical support comes in. Here are 3 benefits of expedited troubleshooting.

AR enhances accuracy and speed in troubleshooting

AR tech support eliminates the need for lengthy explanations and diagnoses by allowing support agents to get a clear view of the problem in real-time. AR tech support softwares, like NewForge Knowledge Place have been developed with the industry in mind. Knowledge Place provides a platform for technicians to share knowledge, search for experts on a specific piece of equipment using AR, and work with Expert AI to create work instructions.

Remote experts can clearly indicate what the problem is with specialized features like adding arrows or circles or sharing schematics all in someone’s line of sight. The technician on the other end of the call gets accurate and clear answers to their troubleshooting questions.

AR minimizes the need for specialized knowledge on site

Often, technical problems require specialized knowledge to identify the root cause and find the right solution. However, with AR, maintenance technicians can receive assistance from remote experts to diagnose and solve complex issues that may require specialized knowledge. The AR technology allows technicians to virtually connect with remote experts who can guide them through the troubleshooting process, minimizing the need for additional support staff and training.

AR reduces downtime

Tech support can help reduce downtime by providing quick and efficient AR solutions to technical problems. Receiving technical support using AR is done by sending a link to an expert or having available experts to search though to make an appointment. The technician can then receive over-the-shoulder assistance by the expert who can augment the technician’s line of view with annotations, circle or draw arrows to the problem, share schematics and walk the technician trough the problem.

By leveraging AR technology, businesses can detect and resolve issues quickly, resulting in minimal disruption to their operations. In addition, AR technology can help businesses provide better customer service by offering a more interactive and engaging experience, helping to improve customer satisfaction.

Improved collaboration

The packaging industry has greatly evolved over the years, from traditional paper and carton packaging to high-end packages with advanced designs. The increasing demand for custom packaging has made collaboration even more important in the packaging industry. Yet, with improvements in technology, packaging companies have found ways to streamline their operations and improve collaboration. Let’s look at 4 ways improved collaboration helps the packaging industry.

Improved communication

Communication is the underlying foundation of collaboration, and the packaging industry is no exception. However, traditional communication methods often fall short in terms of conveying complex packaging designs. With AR, team members can easily share packaging designs, highlight specific parts, and make changes in real time, without being physically present in the same location. This level of communication not only saves time but also streamlines the packaging process, thus improving collaboration among team members.

Enhanced visualization

AR technology allows team members to view packaging designs in 3D and in real-time. Traditional 2D diagrams can be difficult to understand, especially for non-technical team members. With AR technology, all team members, irrespective of their technical expertise, can visualize packaging designs clearly and easily. This makes it easier for team members to collaborate effectively, come up with new ideas and input, and make necessary changes on the go.

Improved efficiency

AR technology can improve efficiency by enabling team members to collaborate closely and quickly. With traditional methods, team members often had to set aside hours to discuss, revise, and make changes to packaging designs. AR technology eliminates the need for time-consuming meetings and long email chains, allowing team members to collaborate remotely and seamlessly.

AR provides an array of beneficial services to the packaging industry that can go a long way in improving operational efficiency and increasing customer satisfaction. Utilizing these technologies for troubleshooting and guidance purposes, as well as providing product information and helping boost sales, can help companies stay ahead of the competition. From improving collaboration and communication to enhancing visualization and efficiency, AR is changing the way businesses operate in the packaging industry.

The post 5 Ways AR Enhances the Packaging Industry first appeared on NewForge Tech.

]]>The post Smart Glasses: The Solution You’ve Been Looking For first appeared on NewForge Tech.

]]>AR software is a powerful tool for industries looking to fight back against the ever-growing lack of resources. And while it can be used on almost any smart device, smart glasses are the number one choice for any hands-on industry.

How are smart glasses changing the game?

You’re Hands-Free!

While we love smartphones and tablets for being an easy and convenient way to get information, they’re always going to be hands-on.

Smart glasses introduce an even simpler way of receiving information.

They allow for a screen to sit in your line of view. That combined with voice-activated software means that you’re getting all the benefits of a tablet or phone without ever having to shift your focus.

Instead of stopping what you’re doing to fumble with your phone, you’re hands-free to complete the task at hand.

But what does hands-free mean to me?

Being hands-free brings its own set of benefits, which can be simplified into the 3 S’s:

Safety

When wearing smart glasses correctly, the view screen is used like a rear-view mirror. Users keep their heads up focusing on the task at hand. Only glancing at their view screen to gather the information they need. This keeps a user more aware of their surroundings than other ways of getting information.

Many smart glasses are also designed with the frontline environment in mind. Most devices are built ruggedized and allow users to wear personal protective equipment (PPE) with them.

Simplicity

Smart glasses make things easy and simple for the end user. Instead of fumbling with a printed set of instructions, now their instructions are in their line of view. And vocal commands are used to easily continue through the steps.

A common misconception about new technology is that it’s difficult for new users.

However, the vocal commands of smart glasses prove to be very intuitive. We find that most people get used to wearing a device within an hour or less.

Speed

Enhanced speed is another benefit of using smart glasses. Getting direct instructions in your line of view takes away the guesswork of “What do I do next?” Meaning time is spent more productively.

For example, one of our customers brought their task completion time down by 41% after introducing smart glasses.

Not only is the speed of getting tasks done enhanced but so is the speed of training. Normally, training new employees can take weeks. But with the intuitive learn-by-doing approach smart glasses provides, that time gets cut down exponentially.

Bridging the skills gap!

We all know that resources are dwindling. There’s less time, people, and skills in the world right now. Skilled laborers are retiring at an alarming rate and their years of expert knowledge are going with them.

How can we bridge the skills gap between the person with years of industry knowledge that’s leaving the workplace and the person just starting out?

The answer is smart glasses. Smart glasses allow for the easy transfer of knowledge in an effective way.

When an expert wears a pair, their processes can be recorded and documented, and then used to create instructions that others can follow.

Instead of getting an expert to sit down and write out their processes, they can take pictures, videos, or notes while doing their task. You no longer have to rely on someone’s memory or handwritten notes when creating instructions.

Smart glasses mean more effective training.

Another issue has arisen from the lack of industry resources: training. Many people are left asking: how can you effectively and quickly train with such a high turnover rate?

The solution is, once again, smart glasses. Smart glasses allow your trainers to spend less time devoted to training and give your workforce being trained a more interactive and inclusive learning experience.

Smart glasses uniquely allow for a guided learn-by-doing approach. The hands-free nature means that people can do a task while, at the same time, being taken through step-by-step instructions.

Instead of helping one person at a time, trainers can remotely monitor all the people they’re training at the same time. Then give extra help where it’s needed. Trainers can use their time more effectively.

What also makes training with smart glasses unique is the digital nature of the instructions. Digital workflows are more interactive and inclusive than other training options.

Voice control and interactive workflow elements, like checklists, keep users engaged in their tasks. Thanks to their digital nature, workflows can also be quickly changed and customized. For example, if your workforce mostly speaks Spanish, a digital workflow can easily be translated to accommodate your needs.

Introducing a whole new world of maintenance

Maintenance has become a struggle for many industries. There are fewer people with expert knowledge to help when things go wrong.

Not only that, but maintenance is a hassle. Having to get vendors to travel to you, waiting on parts, or being put on a waitlist all means wasted time and lost money.

But smart glasses allow for a new approach to maintenance. They let expert help be there without physically being there.

For example, if you have a robot arm go down mid-shift, a worker can put on a pair of smart glasses and use them to call your vendor in a different country. The vendor can see what the worker sees through the camera and give remote help right away.

No more waiting around or paying extreme fees to get someone to travel to you.

Traditional video calls on smartphones and tablets can have a similar effect; however, they aren’t specialized to the industry like many smart glasses and their software are.

Many times, when getting help over a video call, you have to set down whatever device you’re taking the call on to fix the issue. The other person on the line can no longer see what you’re doing thus defeating the whole point of having a video call.

But when you’re hands-free taking the call, that never happens. The person on the other line can watch what you’re doing the entire time.

However, getting help over a traditional video call can still be hard. You get a lot of “Wait, what?”, “It’s too dark”, and “Where?”

Specialized software, designed for smart glasses with the frontline in mind, has taken away all those typical issues you get.

Our software, NewForge Knowledge Place, gives you valuable tools for calls. Like the ability to remotely turn on the flashlight of the device, give a hazard warning, and take screenshots of what the camera sees. Frontline lets you make annotations on the screen, so the other party sees what’s most important. With software like this, you can also pull up schematics, manuals, and PDFs. Making, “What are you talking about?” A question of the past.

Smart glasses and their specialized software provide clarity to maintenance in ways other video calls just can’t. Experts can provide direct help at any time from anywhere, saving you time and money.

Why Smart glasses?

So, when we get asked, “Why smart glasses?” We could give you an exhaustive list of the benefits they’re bringing to the table. But the short answer is they bring clarity, speed, and directness to industries in dire need of it, helping to solve an ever-growing lack of time, people, and skills. (And save you money, on top of that.)

The post Smart Glasses: The Solution You’ve Been Looking For first appeared on NewForge Tech.

]]>The post How Manufacturing Companies Are Using AI And Augmented Reality to Address the Skills Gap first appeared on NewForge Tech.

]]>What is the Skills Gap?

A skills gap occurs when there is a mismatch between what employers need in terms of skills and what job seekers bring to the table. For instance, many employers need workers who are proficient in technology but struggle to find such individuals. This mismatch can be attributed to many factors, including rapidly evolving industry demands, changing job requirements, and the retirement of experienced workers. The most significant consequence of this gap is difficulty in filling job vacancies, which can be detrimental to the economy.

Bridging the Skills Gap: Understanding the Factors That Cause It

The manufacturing skills gap is a growing concern and it is important to understand the factors that contribute to it. Here are the top three causes of the skills gap.

Worker Retirement

One of the leading causes of the manufacturing industry skills gap is the retirement of skilled workers. Many baby boomers who have been working in the manufacturing industry for decades are now retiring, and they take with them years of valuable knowledge and experience. These retirements leave a void in the existing workforce as younger generations are not filling those positions at the same rate.

In order to combat this issue, employers can develop apprentice programs that give younger workers the opportunity to learn from experienced workers and gain the necessary skills for the job.

Challenges With Traditional Training Methods

Another contributing factor to the skills gap is the inadequacy of traditional training methods. Today, workers cannot afford to take extended periods of time off of work to be trained. The traditional “classroom-style” training is no longer practical or effective. Employers need to develop new and innovative on-the-job training methods that can be easily incorporated into the manufacturing workforce. This can be achieved through online learning platforms, mobile apps, and interactive training modules.

Perceptions Related to the Manufacturing Industry

Lastly, many people inaccurately associate manufacturing jobs with low-paying and unskilled work. However, the reality is that today’s manufacturing jobs are high-tech, require a great deal of skill and knowledge, and pay well. It is crucial to change these perceptions and make more people aware of the benefits of working in the manufacturing industry. Employers can do this by offering tours of their facilities, participating in career fairs and events, and offering internships and apprenticeship programs.

Exploring the Top 4 Ways Companies are Using AI and AR to Address Operational Needs and the Skills Gap

The use of cutting-edge technology, such as AI and AR, is transforming the way businesses operate across different sectors. Companies are leveraging these tools to drive efficiency, enhance productivity, and offer an enhanced customer experience. Here are top 4 ways in which companies are using AI and AR to revolutionize their operations.

Assembly

The adoption of AI and AR technology is streamlining the assembly processes in manufacturing facilities. The use of smart glasses and head-mounted displays has made it possible for workers to receive instructions on the assembly line, allowing them to complete tasks with precision and speed. This technology is also reducing the instances of errors, which can often lead to costly delays and even damage to the product. Moreover, the use of AI algorithms is enabling companies to optimize assembly line production, creating a more efficient and effective process.

Inspection

Companies are using AI and AR technology to improve inspection processes, particularly those in manufacturing facilities and construction sites. The use of portable devices, such as tablets and smartphones, equipped with AI-enabled applications, can help workers perform inspections with a higher level of accuracy. These applications are capable of identifying defects, measuring tolerances, and conducting quality checks.

Furthermore, the use of AR technology supports visualization, allowing inspectors to overlay digital instructions and reference materials directly on-site and simplify complicated inspection processes. This removes ambiguity and problems with communication, reduces errors, and speeds up the inspection process.

Remote Support

AI and AR are empowering companies to offer fast and efficient support, even in remote areas. By using AR-enabled mobile devices and head-mounted displays, companies are able to offer remote assistance to workers in the field, enabling them to have digital overlays and real-time visual assistance. This technology makes it possible for field workers to receive expert assistance, irrespective of their location, reducing downtime for the product or workflow systems. For example, Verizon uses smart glasses to increase accuracy and decrease time on site.

Finally, Industries like utilities, oil and gas, and renewable energy are significantly enhancing fieldwork support and experience by leveraging this technology.

Training

AI and AR have revolutionized the way companies conduct staff training sessions across industries. The use of AR-enabled applications provides existing employees with immersive training experiences, enabling them to acquire skills with more efficiency and precision. The technology provides a platform for employees to interact with virtual objects and simulate real-life scenarios. The incorporation of AI algorithms into the training process generates a highly adaptive system that can cater to the individual learning pace. The use of such technologies is also capable of reducing the overall training time, ultimately driving cost savings for the company.

How NewForge helps the manufacturing industry

NewForge Knowledge Place is a revolutionary new online marketplace that bridges the gap between industries in need of specialized knowledge and experts with that knowledge using the power of AR, AI, and smart glasses.

How does it work?

End users simply create an account and search through a digital database of experts in their field. They can then schedule a call with an expert for remote help anywhere in the world, in real-time.

Using the unique AR software for calls, experts can not only see the issue but give clear and concise remote help.

NewForge Knowledge Place also provides Expert AI, a powerful generative AI tool that allows users to get quick troubleshooting answers and easily generate work instructions. NewForge Knowledge Place brings industries the expertise they need when they need it, reducing their downtime, and increasing their ROI.

What sets NewForge Knowledge Place apart from other solutions?

NewForge Knowledge Place is set apart from other maintenance solutions by its unique AR approach. Remote assistance using AR allows an expert to provide help without physically being there.

Many industries turn to video calls on smartphones and tablets for remote assistance; however, their software and hardware aren’t specialized to the industry like smart glasses and NewForge Knowledge Place’s unique software.

Smart glasses allow users to take calls hands-free, meaning the person on the other line can see what you’re doing the entire time. The camera sits in line with a user’s eyes, giving the call a virtual over-the-shoulder experience. No more setting down a phone during a call or having a camera point in the wrong direction.

On top of that, NewForge Knowledge Place’s specialized software makes getting help clear and direct.

Bühler Case Study

The Bühler Group, a global supply chain company, successfully implemented the use of AI and Augmented Reality technology to address their skills gap. The results showed that they experienced many benefits such as an increase in efficiency by 35%, savings of up to $30k per day, a reduction in travel expenses by 55%, and customer satisfaction levels increased by 22%. This implementation has allowed Bühler to utilize the potential of AI and AR technology to bridge their skills gap, benefitting the company as a whole.

By leveraging AI and AR, manufacturers can provide more effective training and development opportunities for current and future employees while minimizing disruption to operations. Ultimately, this could result in improved product quality, better customer experiences, and increased productivity. With the right implementation strategies, AI and AR can be powerful weapons in closing the skills gap and helping manufacturing companies move into the future.

Do you want to learn more about the benefits of AI and AR in the manufacturing industry? Contact one of our specialists today!

The post How Manufacturing Companies Are Using AI And Augmented Reality to Address the Skills Gap first appeared on NewForge Tech.

]]>The post Innovation In Manufacturing: Trends For 2024 first appeared on NewForge Tech.

]]>Advancements in Automation and Optimization Using AI and AR

In recent years, the manufacturing industry has seen a surge in advancements in automation and optimization using AI and AR technologies. These tools provide an excellent level of accuracy and productivity for companies looking to stay ahead of their competitors. Let’s take a look at some of the trends we can expect to see in 2024 that will shape the future of manufacturing.

1. Automation in Production Processes

The implementation of machine learning algorithms is transforming the way manufacturing plants operate. The creation of smart factories, which integrate AI technologies, will automate the production process and improve its accuracy and predictability. Automation enhances the manufacturing process by reducing human error, increasing efficiency, and reducing production costs.

2. Predictive Maintenance Using AI

Real-time data analytics for proactive maintenance is now possible with the utilization of AI. Predictive maintenance predicts equipment failures before they happen, saving time and money, and improving overall equipment effectiveness (OEE). Maintenance personnel are constantly looking for ways to reduce maintenance costs, increase equipment reliability, and minimize downtime. AI technologies further these goals by acting as a watchdog and spotting issues before they evolve into larger problems, thereby reducing downtime and costs.

3. Quality Control Enhancement With AI

AI-powered visual inspection systems are helping to reduce errors and defects in manufacturing. The systems use machine learning algorithms to identify and categorize defects, such as surface scarring, marks, texture problems, and size variations. With these systems in place, manufacturers can detect quality issues in real time, improving the overall quality of the products. This helps manufacturing companies save money by reducing the number of product recalls and broken products.

4. AI-driven Supply Chain Optimization

Demand forecasting and inventory management are critical components of supply chain management, driving business performance. AI algorithms can now identify patterns in sales data to predict demand, configure inventory levels, and manage the supply chain. Using AI reduces supply chain issues, improves efficiency, and reduces time and costs associated with managing the supply chain.

5. Remote Collaboration and Training Using AR

The future of training and collaboration among employees in the manufacturing sector has never been more accessible. AR makes it possible to train employees remotely and interactively. With AR, employees can learn new skills, protocols, and practices while performing the task, increasing speed and efficiency. .Similarly, AR will enable remote troubleshooting, freeing up experts from having to travel to a site to examine an issue. This feature will be essential in reducing downtime and increasing productivity.

6. AR-assisted Maintenance and Repair

AR is expected to significantly impact manufacturing operations. Future manufacturing workers will be equipped with AR-powered head-mounted displays, guiding them through difficult maintenance procedures visually and interactively. With AR, workers can access real-time overlays of instructions and guides, making the repair process more efficient and less time-consuming. Additionally, AR-assisted maintenance enables hands-free operation which improves productivity and helps to prevent accidents.

7. AR-powered Product Prototyping and Design

AR promises to change the way products are designed and prototyped. It will enable engineers and designers to visualize and test prototypes virtually before any physical model is created. This technology will streamline the product development process, reducing lead times, costs, and potential errors. With AR-powered 3D modeling and visualization, engineers can collaborate more effectively, leading to improved product design and manufacturing processes.

8. Enhanced Customer Experiences With AR

AR is expected to change the manner in which customers interact with products. Customers will be able to experience products in virtual and interactive environments, improving customer engagement and satisfaction levels. AR will enable personalized shopping experiences, where customers can virtually interact with products before making a purchase decision.

The Power of Integration: How AI and AR are Revolutionizing Manufacturing

Manufacturing processes are undergoing significant transformations, thanks to the advent of AI and AR technologies. AI has revolutionized the way manufacturers handle data, while AR has transformed the way they visualize and attend to production processes. Here’s a look at what the manufacturing industry trends related to AI and AR offer in terms of benefits and opportunities.

Synergy Between AI and AR Technologies

Artificial Intelligence and Augmented Reality are two distinct concepts that, when integrated, unlock a wide range of benefits in manufacturing. AI is a digital technology that involves training computers to perform human-like tasks. AR is a visual technology that adds digital information to a user’s real-world environment. Therefore, the integration of these two technologies results in intelligent, real-time decision-making systems that deliver actionable insights, support long-term planning, and create new ways for humans to interact with machines.

Collaborative Robots (Cobots) Incorporating AI and AR Technologies

As part of the fourth industrial revolution, AI and AR are increasingly being used to create cobots, or collaborative robots, that can work alongside humans. These robots are equipped with advanced AI algorithms and sensors that enable them to interact with their environment, recognize objects, interpret human gestures, and learn from their own experiences.

The integration of AI and AR technologies into these cobots allows for real-time data collection, enabling the robot to make decisions quickly and accurately. Additionally, AR can be used to provide visual instructions to cobots for assembly and maintenance tasks. This helps reduce downtime and enhances accuracy in production processes.

What Are the Benefits of Combined AI and AR Technologies in Manufacturing?

The integration of AI and AR technologies in the manufacturing sector offers a number of benefits, such as improved efficiency and productivity, enhanced safety and reduced errors, cost savings, and waste reduction. Let’s take a closer look:

- Improved efficiency and productivity: By combining AI and AR technologies, manufacturers can reduce production times and costs while enhancing the accuracy of production processes. This technology combination also increases communication between machines and workers, making it possible to respond quickly to changes in demand or unexpected problems.

- Enhanced safety and reduced errors: The integration of AI and AR technologies enables machines to detect potential risks, reducing the chance of accidents or serious incidents. Additionally, by providing workers with real-time guidance and information, AR reduces human errors and increases production accuracy.

- Cost savings and waste reduction: The introduction of AI-powered systems in manufacturing helps to reduce costs associated with manufacturing workforce, materials, energy consumption, and maintenance. By streamlining production processes and eliminating manual labor, companies can save money on wages and reduce waste.

Navigating the Challenges and Considerations When Adopting AI and AR in Manufacturing

Like with any other technology, adopting AI and AR comes with its own set of challenges and considerations. Let’s explore some of the common challenges that manufacturers often face when adopting these technologies, and what measures businesses can take to navigate them successfully.

Data Security and Privacy Concerns

The fear of confidential data being breached creates a heightened sense of risk. Manufacturers must understand the vulnerabilities that their manufacturing process might have and implement the right measures to ensure that their data is secured. These might include encrypting data before it’s stored or transferred, and implementing multi-factor authentication protocols to secure access to sensitive data.

Workforce Training and Skill Development

AI and AR require staff to have the necessary skills to operate the technology efficiently. This has created a skills gap and a need for workers to receive on-the-job AI and AR training. Manufacturers must invest in upskilling their workers to ensure that they’re kept up-to-date with technological advancements so that they can perform their tasks efficiently. This can be achieved through regular training on new technologies and skills development programs that integrate AI and AR usage into the team’s work routines.

Ethical Implications of AI and AR in Manufacturing

As AI and AR penetrate manufacturing processes, there are ethical implications that businesses must consider. A good example of this is the question of “worker replacement” with AI and AR. This calls for ethical considerations by businesses so that they don’t sideline their employees from the manufacturing process. Manufacturers should ensure that their employees’ responsibilities and working environment are not compromised by deploying AI and AR to perform duties previously done by humans.

AI and AR are making their presence in the manufacturing industries. By leveraging these technologies, manufacturers can benefit from improved efficiency and productivity, enhanced safety and reduced errors, cost savings, and waste reduction. Although there are challenges that come with adoption such as data security concerns and workforce training needs, by proactively addressing such issues businesses can remain competitive in the manufacturing industry and continue to reap the rewards of AI and AR technologies. With these main points in mind, businesses can confidently navigate through the evolving trends of AI and AR in manufacturing for 2024.

Do you want to learn more about the benefits of AI and AR in the manufacturing industry? Contact one of our specialists today!

The post Innovation In Manufacturing: Trends For 2024 first appeared on NewForge Tech.

]]>The post Understanding Augmented Reality: Fundamentals & Real World Applications first appeared on NewForge Tech.

]]>One of the most frequently asked questions that we get at NewForge is, “What is augmented reality?”

According to the Oxford dictionary, “augmented reality (AR) is a technology that combines computer-generated images on a screen with the real object or scene that you are looking at.”

To put it simply, augmented reality is the enhancing (or augmenting) of your view of the real world using an overlay of computer-generated media.

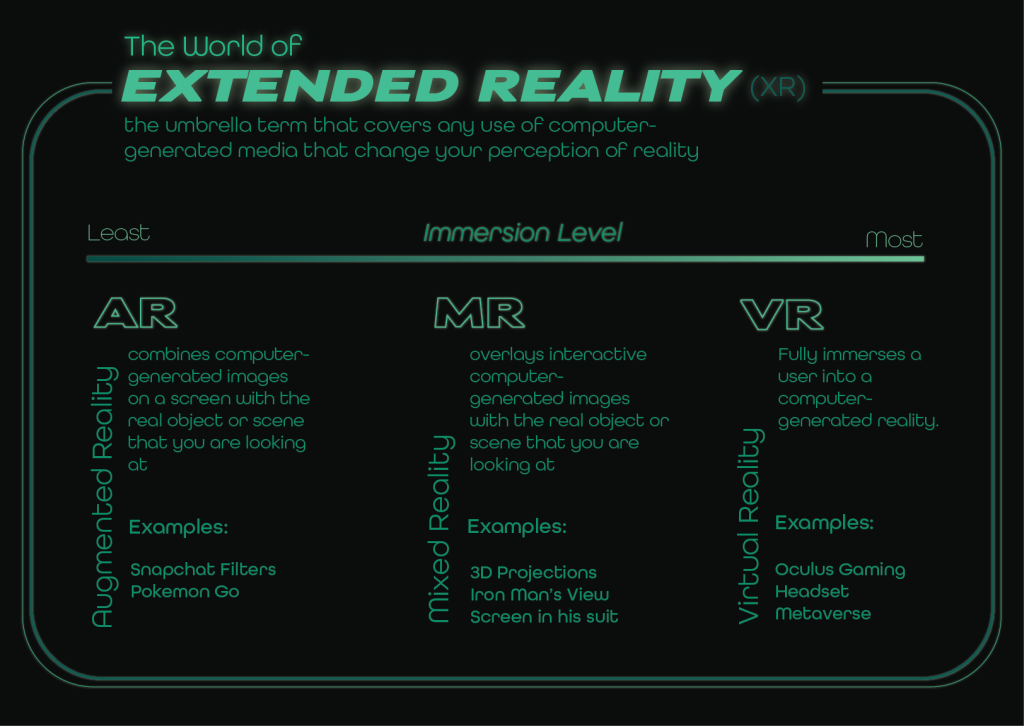

The terms, extended reality (XR), mixed reality (MR), and virtual reality (VR) are often used in conjunction with augmented reality; but, if you’re not in the industry you may not know what these terms mean.

Extended reality (XR) is the umbrella term that covers any use of computer-generated media to change your perception of reality. Augmented Reality exists under the XR umbrella, along with MR and VR.

What makes AR, MR, and VR different is how immersive they are. On one end, you have VR which fully immerses a user into a computer-generated reality. And on the other end, you have augmented reality which only adds a computer-generated overlay to the real world. Between the two, you have mixed reality, which isn’t fully immersive like VR but more so than AR.

You may not realize it, but you’ve more than likely used AR before. Whether you were a big Pokémon Go fan in 2016 or if you love using filters on your Snapchat selfies, AR has become fairly commonplace.

A brief history of AR

Augmented reality saw its first surge in popularity in the 2010s. With big companies starting to use it in advertising and the introduction of Snapchat and Google Glass. However, it has been around for much longer than that.

Author, L. Frank Baum, explored the concept of a pair of smart glasses in his novel, The Master Key, all the way back in 1901.

In the 60s, the Sensorama was introduced to the world as the first attempt at augmenting reality using technology. The idea was a booth that would use all 5 senses to take immersion to another level. The booth came complete with screens, fans, scent emitters, and a stereo sound system.

The first AR head-mounted displays were also produced in the 1960s in Salt Lake City. However, these were extremely heavy, having to be suspended from the ceiling to be worn.

The idea of smart glasses and head-mounted displays was explored more throughout the 80s, but we didn’t see any significant changes until the introduction of the Google Glass.

Google’s introduction of the Google Glass in 2012 is what brought smart glasses to the consumer landscape. Along with the introduction of Snapchat filters in the 2010s, augmented reality officially hit the mainstream consciousness.

This sparked an exploration of the different applications for AR and smart glasses. And not just within the consumer market, but in fields like manufacturing and medical.

Applications of AR

Many people have come to associate AR with things like gaming and Snapchat filters; however, AR has an endless number of uses that are more than just “for fun.”

AR enhances learning, aids in connecting people, simplifies any process that has steps, and helps with quality control. There’s a possible use case for augmented reality software in any field that could benefit from these things.

Imagine being dropped into a manufacturing plant and asked to build a dryer. You have all the materials in front of you but have no idea what to do with them.

Then you’re provided with a pair of AR smart glasses. When you put them on, you see step-by-step instructions through the head-mounted display.

The instructions guide you on which parts you’ll need, how and where to place them, and which tools to use to create a functioning dryer.

At the end of your process, you’re almost done but can’t seem to get one piece to fit. Through your headset, you call a dryer expert. The expert on the other end sees what you see through the camera, in real-time. They use AR tools to circle where you have the issue; in this case, an incorrect-sized bolt.

With that, you just made a functioning dryer.

This scenario is realistic as to how AR is being used in manufacturing today. It provides a way for manufacturers to get information while being hands-free to complete their tasks. And on top of that, it simplifies their training and processes, meaning things are getting done faster without quality suffering.

None of this is exclusive to manufacturing though.

In logistics, end users can use interactive work instructions to find the products they’re looking for in a warehouse and verify their inventory items as they pick an order, meaning nothing gets left out. AR helps warehouse workers increase their productivity and lower order errors along with many other benefits.

Smart glasses and AR are being adopted into operating rooms, helping to reduce the number of complications in surgery. For example, in South Korea, anesthesiologists did a study using head-mounted AR displays to insert radial arterial lines into patients. The smart glasses increased the success rate by 15.5% and the speed at which the procedure was done.

AR is even being used in tourism, education, navigation, marketing, architecture, design, and fitness. The world of extended reality is truly unlimited.

The Future of AR

With such a variety of uses, we will only see an increase in AR use as time goes on. People have only begun scratching the surface of what AR can do in recent years. The introduction and increasing popularity of things like VR gaming and the Metaverse shows that a boom in extended reality is coming. Will you be ready for it?

Sources

A brief history of Augmented Reality – Numerized

What’s the Difference Between AR, VR, and MR? | The Franklin Institute (fi.edu)

The post Understanding Augmented Reality: Fundamentals & Real World Applications first appeared on NewForge Tech.

]]>The post The Hard Truth of Augmented Reality:Enhancing Resources with AI first appeared on NewForge Tech.

]]>The AR landscape is littered with the remnants of grand ambitions, projects stalled in the pilot phase, and companies who dared to dream but ultimately fell short. Notably, AR hardware companies like ODG and DAQRI collapsed under the weight of their ambitions, while tech giants like Google and Microsoft scaled back their AR ventures significantly.

The key challenges hampering AR’s adoption in the manufacturing industry can be traced back to two principal issues. First, there is the constant struggle to find specialized knowledge on equipment to use in AR content. Secondly, the creation of AR work instructions presents a logistical nightmare of transforming intricate operational procedures into AR-friendly formats.

The gravity of these roadblocks is evident from the sheer number of AR initiatives that remain trapped in the pilot phase. In our experience and speaking with other AR industry leaders, many AR projects, despite promising beginnings, never make it to full-scale deployment, hampered by the formidable barriers of expertise procurement and AR content creation.

As we’ve seen, throwing more technology at a problem doesn’t make it go away.

One of the biggest hurdles we hear from manufacturing personnel is the availability of time and skilled people to manage and scale technology projects.

On one hand, manufacturers possess huge repositories of procedures, work instructions, and standard operating procedures (SOPs). On the other, reworking these existing resources into AR-compatible formats, despite potential ROI, can seem like an insurmountable task when there’s no personnel with the ability or time to do so.

Despite these challenges, there’s a beacon of hope: the marriage of generative artificial intelligence (AI) and crowd-sourced expertise. Platforms such as NewForge Knowledge Place utilize generative AI to draw upon existing documents and user prompts, creating dynamic work instructions. The painstaking process of manual recreation is eliminated, bringing new life to existing SOPs.

These AI-generated instructions can then be sent to smart glasses or AR devices, providing real-time, hands-free guidance. To ensure accuracy and practicality, human experts then review and curate these instructions. This harmony of AI and human expertise paves the way for high-quality, reliable work instructions.

Further, crowd-sourcing is employed to amass a wealth of specialized knowledge on various types of equipment. This information can be accessed exactly when and where it’s needed, effectively addressing the challenge of delivering specialized knowledge when personnel cannot find the resources they need to resolve a costly problem.

Platforms like NewForge Knowledge Place could be the lifeline the AR industry desperately needs. If the blend of generative AI and crowd-sourced knowledge can be scaled and adopted widely, it could be the catalyst that finally propels AR out of the pilot phase and into mainstream usage.

The AR industry’s journey has been fraught with challenges and setbacks, yet it stands on the brink of a transformative era. By melding AI, AR, and crowd-sourced knowledge, we’re venturing into uncharted territory, ripe with potential. This could be the breakthrough that finally enables AR to reach its true potential, propelling it to the lofty heights initially predicted. In the face of these emerging trends, one can’t help but watch in anticipation, wondering if this will finally be AR’s moment in the sun.

The post The Hard Truth of Augmented Reality:Enhancing Resources with AI first appeared on NewForge Tech.

]]>The post Unlocking the Potential of Assisted Reality first appeared on NewForge Tech.

]]>Manufacturing is an industry in constant evolution. The pursuit of efficiency, productivity, and safety has driven manufacturers to explore cutting – edge technologies. One such innovation, assisted reality, is making waves in the manufacturing sector, revolutionizing the way tasks are accomplished, problems are solved, and knowledge is shared. In this blog post, we’ll dive deep into the world of assisted reality, exploring its applications, benefits, and the pivotal role of NewForge Knowledge Place in driving this transformation.

The Power of Assisted Reality

Assisted Reality Defined: Assisted reality refers to a technology that blends the real world with digital elements, enhancing a user’s perception and interaction with their environment. In manufacturing, it’s much more than just a buzzword; it’s a game-changer.

Assisted Reality in Action: Instant Virtual Help

Imagine a scenario in a manufacturing plant where a maintenance technician encounters a complex issue with a piece of equipment. Traditionally, this could lead to a time-consuming process involving phone calls, emails, and perhaps even bringing in an expert from another location. However, with assisted reality, this process becomes remarkably streamlined.

- Immediate Troubleshooting: In our scenario, let’s call our technician “Javier.” The very first check Javier performs is to ensure there’s no voltage present—an essential safety step. However, before he can even ascend to the equipment panel, he faces a hurdle.

- Call for Support: Javier realizes there’s an issue he can’t resolve on his own. He decides to call for support. In this case, the expert he needs isn’t physically present. Instead, they are situated at an office, miles away. But thanks to assisted reality, the expert can see precisely what Javier is experiencing through his smart glasses.

- Collaborative Troubleshooting: This collaborative approach allows them to troubleshoot the problem effectively. In this case, the issue was a directive for Javier to make a connection that was already occupied by another customer. The remote expert analyzes the situation, guiding Javier to the solution. He even marks up Javier’s view with visual cues to ensure a smooth resolution.

- Error-Free Repairs: The beauty of this setup lies in its precision. With real-time visual communication and guidance, there’s minimal room for error. Javier and the expert work together seamlessly to complete the repair.

Enhancing Plant Operations

Efficiency Unleashed: Now, let’s transition to in-plant operations. Consider a traditional workflow where a worker must repeatedly switch between a piece of equipment they’re inspecting and a computer where they document their findings.

In contrast, a worker equipped with smart glasses can follow instructions hands-free. They see the instructions in their field of view, take measurements, and verbally record their findings. This process is not only efficient but also remarkably accurate.

For example, using devices like the RealWear HMT-1, workers can decrease completion times by a staggering 51%. This translates into significant time savings and enhanced overall productivity.

Choosing the Right Assisted Reality Tools

Diverse Hardware Options: Assisted reality offers a diverse selection of hardware devices, each tailored to specific needs and preferences. Whether you require a more robust solution, have specific PPE requirements, or are working within a strict budget, there’s a device that suits your unique needs.

Contact the NewForge team to learn about which device would suit your needs best.

Selecting Suitable Software: Similarly, there is a plethora of assisted reality software suites available. Some are tailored specifically for manufacturing, while others are more generic. Ease of use and cost-effectiveness are critical factors to consider. Enter NewForge Knowledge Place…

NewForge Knowledge Place: A Collaborative Core

Expertise Marketplace: The Knowledge Place is a hub where experts from various backgrounds offer their services. It centralizes knowledge, providing access to work instructions and collaborative troubleshooting.

A User-Friendly Approach: Using assisted reality is remarkably user-friendly. The platform aims to provide easy access to a marketplace of experts, facilitating seamless collaboration between your maintenance staff and knowledgeable professionals.

Simplified Deployment: The platform takes care of the intricacies of hardware and software selection and deployment, ensuring a smooth experience for end-users.

Reduced Costs and Enhanced Productivity: Connecting your maintenance personnel with a broader pool of experts reduces costs significantly. Travel requirements are minimized, leading to enhanced productivity and ultimately cost savings for your facility.

Become an Expert & Get Paid

Becoming an expert on the platform is a very simple process. You can request to join and, once approved, complete your profile, showcasing your skills and experience.

Experts have the opportunity to share their knowledge and get paid for it. The platform compensates experts for providing expertise to customers they might not have reached otherwise.

The Bigger Picture

Unlocking Knowledge and Expertise: Access to on-demand information and expertise presents a vast potential. Skilled technicians can leverage the knowledge of seasoned professionals to identify and solve equipment problems using assisted reality. This unlocks efficiencies, reduces downtime, and ultimately bolsters productivity and plant capacity.

Profit Margins and Employee Retention: The implementation of assisted reality leads to higher profit margins and improved employee retention. For instance, one organization reduced its engineer travel budget by 55%. Simultaneously, it introduced a new revenue stream by offering assisted reality as a service to end customers, gaining a decisive edge over competitors. Moreover, this approach contributes to a reduced carbon footprint, aligning with sustainability goals.

In summary, assisted reality is revolutionizing the manufacturing landscape by fostering collaboration, reducing costs, and enhancing productivity. It’s a game-changing technology with far-reaching implications for the industry’s future.

The post Unlocking the Potential of Assisted Reality first appeared on NewForge Tech.

]]>The post NewForge Knowledge Place: The New Face of Equipment Maintenance first appeared on NewForge Tech.

]]>The ongoing shortage of skilled workers and the growing complexity of machinery have only made the issue worse.

But what if there was a solution that could bring you the machinery knowledge you need, streamlining your operations rather than adding to your workload?

NewForge, a leader in augmented reality (AR) and smart glass solutions in manufacturing and logistics, is publicly launching the beta of their new platform, NewForge Knowledge Place.

Through the combined power of artificial intelligence and augmented reality, NewForge Knowledge Place is revolutionizing equipment maintenance, delivering instant on-demand knowledge, reducing downtime and increasing ROI.

What is NewForge Knowledge Place?

NewForge Knowledge Place is the revolutionary new online platform that bridges the gap between equipment questions and expert answers using the power of AI and AR.

Think of it as the central hub for all your equipment maintenance questions with powerful avenues for accessing instant expert knowledge.

Knowledge Place provides ExpertAI, the powerful tool that uses generative AI to give instant help. Not only does ExpertAI provide quick troubleshooting answers, but it also creates customized work instructions that capture and streamline processes.

Users can also search through Knowledge Place’s digital database of experts and schedule a call with them to receive remote help in real time. Through Knowledge Place’s AR software, experts can not only see the issue but also give clear and concise assistance.

How does it work?

ExpertAI

ExpertAI, the cutting-edge feature within Knowledge Place, empowers users with the instant, on-demand knowledge they need to tackle their equipment challenges. Through the power of artificial intelligence, ExpertAI streamlines troubleshooting and the work instruction creation process.

ExpertAI operates much like chatting with an AI assistant; you prompt it with your equipment-related questions or needs, and it generates tailored solutions for you.

While these could be simple answers to troubleshooting questions, what sets ExpertAI apart is its ability to generate comprehensive and detailed work instructions that can be sent to smartglasses or any other mobile device.

This gives your workforce on-the-go step-by-step guides to their operations.

ExpertAI transforms complex SOPs, manuals, and guides into something anyone can use.

When combined with the power of AR and smartglasses, these AI-generated instructions are used in heads-up displays, letting users get all their processes hands-free. Hands-free instructions equate to increased productivity and a reduction in error and downtime.

Prior to ExpertAI, transforming knowledge into AR work instructions was a manual effort that took time that many people just don’t have. Now it’s a simple process, giving anyone the ability to tap into the power of AR.

ExpertAI is more than just a tool, it’s a game-changer for industries seeking greater efficiency and productivity.

Remote Support

NewForge Knowledge Place comes equipped with a database of equipment experts that users can easily book time with and get remote help from anywhere at any time.

Instead of waiting for an expert or paying extreme fees to get them to travel to you, Knowledge Place lets you get the help you need to get back up and running instantly.

NewForge Knowledge Place is set apart from other maintenance solutions by its unique AR approach.

Many industries turn to video calls on smartphones and tablets for remote assistance; however, their software and hardware aren’t specialized to the industry like NewForge Knowledge Place and smartglasses are.

Smart glasses allow users to take calls hands-free, meaning the person on the other line can see what you’re doing the entire time. The camera sits in line with a user’s eyes, giving the call a virtual over-the-shoulder experience. No more setting down a phone during a call or having a camera point in the wrong direction.

On top of that, NewForge Knowledge Place makes getting help clear and direct with specialized software features for calls.

Specialized Calling Features include the ability to:

- Take screenshots